YEARS OF EXPERIENCE

Infraserv GmbH repairs not only new generation vacuum pumps and components, but also a wide range of products that are no longer produced or repaired by the manufacturers.We focus on the price/performance ratio. No unnecessary blanket repairs are carried out. We coordinate with you!

With regular training, workshops, advanced training and further education, we ensure that our technicians have the necessary knowledge to guarantee the best possible service for you.

Repair service

Vacuum pumps repair

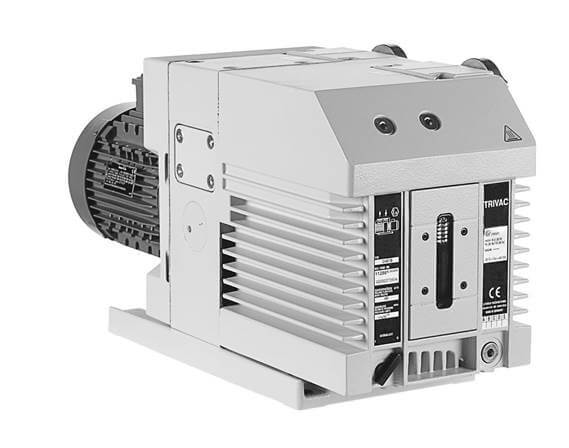

Rotary vane pumps

Vacuum pumps repair:

Rotary vane pumps: defective and dirty pumps are restored to a nearly new condition. It is not always necessary to overhaul the entire pump, often the defective pumps can already be repaired by the targeted replacement of wear parts, such as slide valves and bearings. Maintenance work is carried out in accordance with the manufacturer’s specifications. If necessary, stators and rotors are also replaced; we coordinate this with the customer in advance.

Repair procedure:

- Receipt of the Rotary vane pump, e.g. via on-site pickup service or freight forwarder

- Inspection and testing of the pump

- Disassembly

- Oil disposal and, if necessary, PFPE oil regeneration

- Cleaning in our 3-stage cleaning line (decontamination if necessary)

- Assembly of the pump according to manufacturer’s instructions and specifications

- 24-hour test run with documentation and final inspection sticker

- Painting

- Delivery

Infraserv Vakuumservice has been performing backing (löschen) vacuum pump repairs since 1993. ISO 9001:2015 certification is a guarantee of this. A motivated service team of technicians and engineers, a state-of-the-art workshop, an environmentally friendly cleaning line consisting of an ultrasonic bath, glass bead blaster and propanol drying system, and an extensive test facility to check repaired pumps for all important parameters before delivery.

Vacuum pumps repair

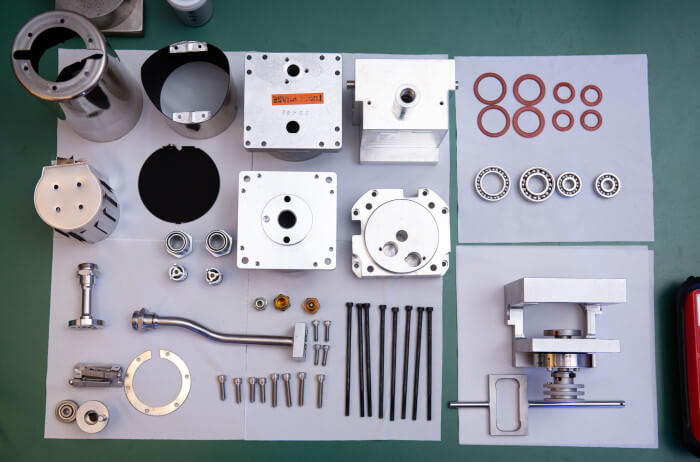

Dry running vacuum pumps

In order not to pollute our customers’ process-relevant areas with hydrocarbon compounds, dry-running vacuum pumps are serviced and repaired at appropriately clean workplaces.

Elaborate repair and adjustment tools are necessary for this type of pump. After the repair work, all important functions are tested with special test equipment and corrected if necessary.

Vacuum pumps repair

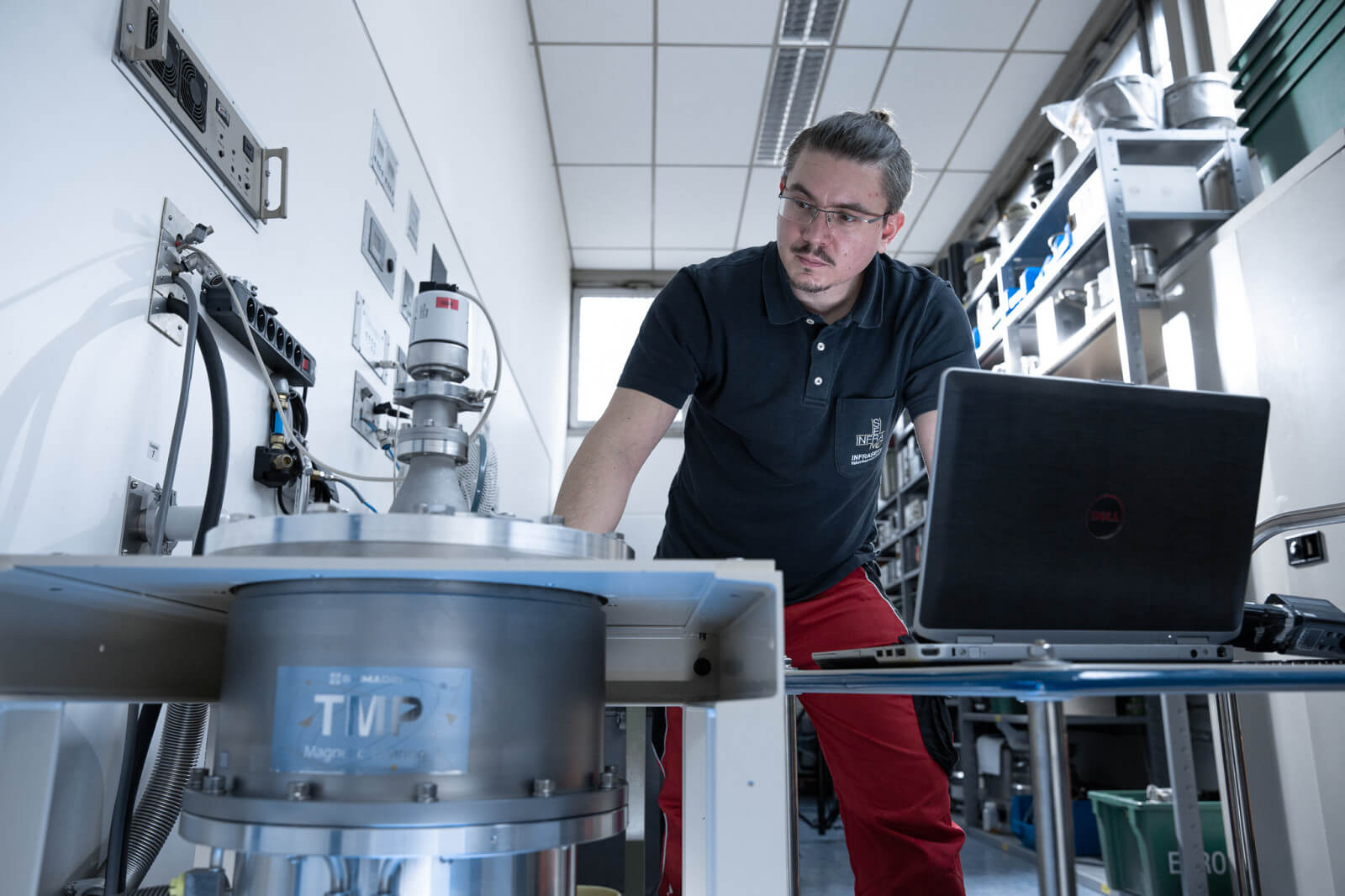

Turbopumps

Repair and maintenance work on turbomolecular pumps is carried out in accordance with precisely defined procedures (internal work instructions according to ISO 9001). Possible contamination must be reported by the user via contamination declaration. In order to protect the health of our employees, in the event of critical contamination, service work is preceded by neutralization in accordance with regulations. This is followed by a detailed diagnosis of the pumps. For later verification, external as well as internal damage is recorded and documented.

Within the scope of this documentation, it is often possible to identify the causes of damage. After the cost estimate has been prepared and approved by the customer, the repair work is carried out in accordance with the manufacturer’s specifications. This includes individual activities such as inspection and adjustment work, cleaning, replacement of defective parts, balancing of the rotor, test runs, etc..

Defective control units (frequency controllers) and other electronic components are repaired and adjusted in our electronics workshop.

-

Manufactorer:Pfeiffer Vakuum

-

Type:TMH 520

-

Pumping Speed:300 l/s

-

Final Pressure: Without gas ballast< 5 x 10-11 mbar

-

Final Pressure: With gas ballast

-

Power Connection:

-

Power Consumption:

-

Inlet Flange:DN ISO K 100

-

Condition:

-

Warranty:

-

Operating Fluids:

-

Miscellaneous:

-

Manufactorer:Pfeiffer Vakuum

-

Type:TMH 260

-

Pumping Speed:210 l/s

-

Final Pressure: Without gas ballast< 1 x 10-8 mbar

-

Final Pressure: With gas ballast

-

Power Connection:

-

Power Consumption:

-

Inlet Flange:DN ISO K 100

-

Condition:

-

Warranty:

-

Operating Fluids:

-

Miscellaneous:

-

Manufactorer:Oerlikon Leybold

-

Type:Turbovac 1000

-

Pumping Speed:850 l/s

-

Final Pressure: Without gas ballast10 x -10 mbar

-

Final Pressure: With gas ballast

-

Power Connection:

-

Power Consumption:

-

Inlet Flange:DN ISO K160 auf 200

-

Condition:

-

Warranty:

-

Operating Fluids:

-

Miscellaneous:

-

Manufactorer:Oerlikon Leybold

-

Type:Turbovac 1000

-

Pumping Speed:850 l/s

-

Final Pressure: Without gas ballast10 x -10 mbar

-

Final Pressure: With gas ballast

-

Power Connection:

-

Power Consumption:

-

Inlet Flange:DN ISO K160

-

Condition:

-

Warranty:

-

Operating Fluids:

-

Miscellaneous:

-

Manufactorer:Oerlikon Leybold

-

Type:Turbovac 1000

-

Pumping Speed:850 l/s

-

Final Pressure: Without gas ballast10 x -10 mbar

-

Final Pressure: With gas ballast

-

Power Connection:

-

Power Consumption:

-

Inlet Flange:DN ISO K160

-

Condition:

-

Warranty:

-

Operating Fluids:

-

Miscellaneous:

-

Manufactorer:Oerlikon Leybold

-

Type:Turbovac 1000 C

-

Pumping Speed:850 l/s

-

Final Pressure: Without gas ballast10 x -10 mbar

-

Final Pressure: With gas ballast

-

Power Connection:

-

Power Consumption:

-

Inlet Flange:DN ISO K160

-

Condition:

-

Warranty:

-

Operating Fluids:

-

Miscellaneous:

-

Manufactorer:Pfeiffer Vakuum

-

Type:TMU 261

-

Pumping Speed:210 l/s

-

Final Pressure: Without gas ballast< 1 x 10-7 mbar

-

Final Pressure: With gas ballast

-

Power Connection:

-

Power Consumption:

-

Inlet Flange:DN 100CF auf ISO K 100

-

Condition:

-

Warranty:

-

Operating Fluids:

-

Miscellaneous:

Vacuum pumps repair

Cryopumps

Infraserv repairs and maintains most of cryogenic pumps on the market:

- CTI Torr / CTI on Board

- ULVAC

- SHI-APD / Balzers

- Genesis

- Varian / EBARA (depending on condition)

Leybold - Sumitomo

Infraserv Cryopumps Standard Repair:

- Disassemble cold head, clean, rework, adjust valves & valve clearance, assemble cold head with new parts (O-rings, seals, bushings, bearings, aeroquips)

- Disassemble displacer, clean lead shot if necessary. Bake out Displacer, Lead Shot, assemble, renew Seals

- Polish cold fingers

- Disassemble pump body, clean, refurbish clearance (recoat)

- Renew carbon part (15K con. array) and resurface if necessary

- Complete pump. Evacuate to test site, perform leak and sniff test

- Test run for 24 hours with appropriate compressor

- For on board models, zero the module, replace the backup battery and check the RS interface

- Also check backup battery and replace if necessary

- Pump is delivered sealed, if possible and desired evacuated with blind flange

- Test document is enclosed

Cryogenic systems are used in the field of low-temperature technology, cryogenics (Greek “cold”). Cryogenics is the generation of low temperatures <123 Kelvin. These temperatures affect the thermodynamic properties of elementary particles. Cold surfaces are able to condense gases on the correspondingly cooled surfaces and bind them in the process (surface binding). Non-condensable gases are adsorbed at low temperatures using activated carbon. Thus, a wide range of gases can be pumped. Cryogenic systems usually consist of a refrigeration unit (refrigerator), cryopump and cryotherapy compressor. The low temperatures are generated by expanding high gas pressures, which are achieved by using special compressors that can compress helium. With particularly pure helium, temperatures down to about 1K can be achieved. These systems are free of hydrocarbons and are therefore preferably used in semiconductor, coating and similar processes within the industry. Cryogenic systems are also required in basic research and applications with superconducting materials. Examples of cryogenic applications:

- Atomization of metals

- Ion implantation

- Vapor deposition processes

- Electron beam welding

- Plasma technologies

- Superconducting area

Do you have any questions or suggestions? Call us or send us a direct message.

Vacuum pumps repair

Compressors

Maintenance of He-compressors includes checking of technical functions, tightness and safety components. In case of contamination of the helium circuit, it is professionally decontaminated. The cooling circuit is checked for proper flow and cleaned if necessary.

The adsorber cartridge is replaced after the permissible operating hours have elapsed. It is also possible to use modified adsorber cartridges, which are reusable, cheaper and more sustainable.

Vacuum pumps repair

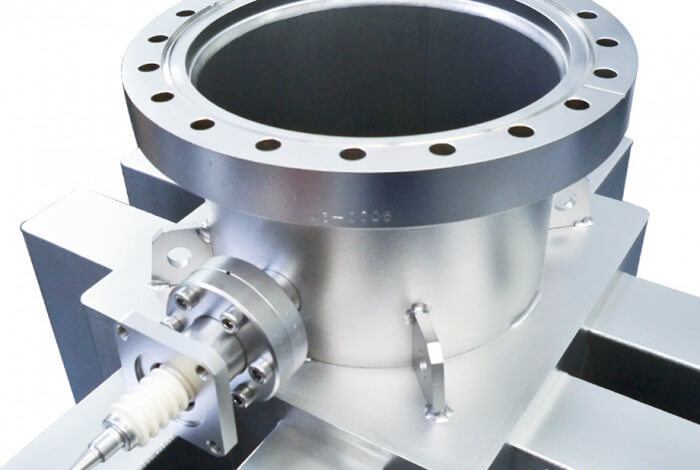

Ion getter pumps

Ion getter pumps (IGP), also called ion atomizer pumps, are ultra-high vacuum pumps which are mainly used in processes where very low pressures (<10-11 mbar) and low vibration environment are required. The working principle of an ion getter pump is electron impact ionization. There they can be chemically bound or implanted and are thus removed from the residual gas. Chemically reactive molecules are also bound without prior ionization when they strike a getter material (usually titanium). This type of pump only works if high vacuum has already been achieved. Ion getter pumps are not very suitable for noble gases because pumped off noble gas cannot be chemically bound and may be released again. Examples of applications:

- Electron scanning microscopy

- Plasma technologies

- Chemical and biological processes

Translated with www.DeepL.com/Translator (free version)

When repairing ion getter pumps, special attention must be paid to cleanliness, as outgassing would severely impair pump performance or processes. Depending on the design, the complete overhaul of ion getter pumps includes the renewal of the cathode plates or the titanium grids as well as the complete overhaul of the anode cylinders, high-voltage feedthrough, attached parts and the pump body. The attached magnets are not required for the overhaul, as only a flashover test is performed. We are also able to overhaul the smaller disposable pumps (up to 20l), which are usually disposed of after consumption. This saves high costs, since a new acquisition is no longer necessary. Ion getter pumps are delivered by us after the dry heating, immediately closed with a flange and evacuated. The test run of the ion getter pumps overhauled/regenerated by us is limited to a flashover test. This means a high voltage test with 6KV. This is the guarantee for an intact IGP. We also have great experience and knowledge in the field of ion getter pump and help to optimize the vacuum process at the customer.

Do you have any questions or suggestions? Call us or send us a direct message.

Vacuum pumps repair

Calibration of vacuum gauges

Vacuum gauges and measuring cells are compared or calibrated within the scope of our test equipment regulations. Our reference measuring cells are re-certified annually by authorized calibration laboratories.

If necessary, the measuring cells are maintained and repaired. All calibration results are documented and passed on to the customer.

Vacuum pumps repair

Leak Detectors

Infraserv GmbH can service and repair the following leak detectors in its specially equipped workshop. For other devices, simply ask:

- Alcatel

- Pfeiffer

- Alcatel

- Oerlikon Leybold

- Ulvac

- Varian